Welcome to the cutting-edge world of trenchless pipe repair, a domain where traditional digging methods become obsolete. At Trenchless Pipe Repair of NH, we specialize in providing top-notch, minimally invasive solutions for your pipe repair needs. Our focus today is on a revolutionary technique known as UV Curing—a method that not only saves your landscape but also enhances the longevity and reliability of your plumbing systems.

For homeowners, management companies, and operators of multi-unit buildings, understanding the options available for maintaining infrastructure is crucial. UV Curing is a standout choice, offering a blend of efficiency and effectiveness. Whether you’re encountering pipe issues for the first time or looking for better repair solutions, this guide will illuminate the benefits and processes of UV Curing in trenchless pipe repair.

What is UV Curing?

UV Curing is a state-of-the-art technology used in the trenchless rehabilitation of pipes. This method involves the use of ultraviolet (UV) light to cure resin in the pipe lining, solidifying it to form a robust, new pipe within the old one. Unlike traditional methods that require extensive excavation, UV Curing is performed through existing access points, reducing disruption and preserving the surrounding environment.

This technology is not only innovative but also environmentally friendly and highly efficient. It’s designed for situations where speed and minimal disruption are paramount. From small residential fixes to large-scale commercial projects, UV Curing offers a versatile solution to a range of pipe repair challenges.

Advantages of UV Curing Over Traditional Methods

Choosing UV Curing comes with a host of advantages that make it superior to traditional pipe repair methods. Here are a few key benefits:

- Speed of Repair: UV Curing significantly cuts down repair time. Traditional methods can take days or even weeks, whereas UV curing can be completed in just a few hours.

- Cost Efficiency: With less digging and disruption, the overall cost of repair decreases. This is because there is less labor involved and minimal restoration required post-repair.

- Longevity and Durability: The UV-cured liners are incredibly resilient and can extend the life of your pipes by up to 50 years. This means fewer repairs and less maintenance over time.

- Environmental Impact: With no need for extensive excavation, there’s minimal environmental disruption. This method is safer for surrounding ecosystems and reduces the carbon footprint associated with pipe repair.

UV Curing is not just a repair method; it’s a long-term investment in your property’s infrastructure. By choosing this advanced technology, you’re opting for a solution that offers durability, reliability, and sustainability.

How UV Curing Works

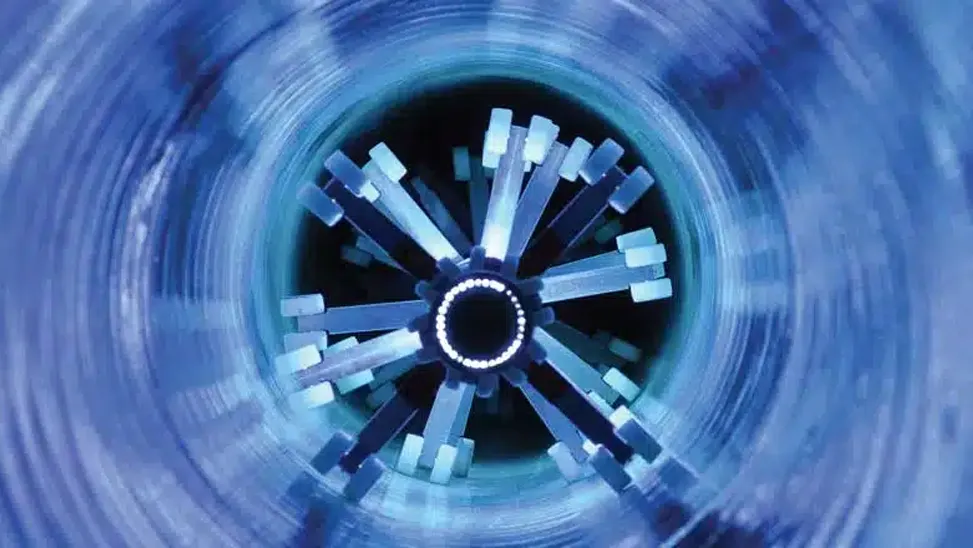

Understanding the mechanics of UV Curing can help demystify why it’s such an effective method for pipe repair. The process begins with the insertion of a liner soaked in a special resin into the damaged pipe. This liner is then inflated to adhere to the interior surface of the existing pipe, ensuring it covers all defects and cracks. Once in place, a UV light train is sent through the liner, which activates the resin. This causes it to harden quickly, effectively creating a new pipe within the old one.

The entire curing process is monitored by CCTV, allowing for precise control and ensuring the liner is perfectly formed without any gaps or misalignments. The result is a seamless, durable pipe with enhanced flow characteristics and a significantly extended lifespan.

Applications of UV Curing in Residential and Commercial Properties

UV Curing technology is incredibly versatile, making it suitable for a wide range of applications in both residential and commercial settings. Here’s how different properties can benefit from this technology:

- Residential Homes: For homeowners experiencing issues like root intrusion or aging sewer lines, UV Curing offers a quick, non-destructive repair solution that keeps yards and gardens intact.

- Commercial Facilities: Commercial properties, including office buildings and shopping centers, often need fast repairs to minimize business interruptions. UV Curing’s rapid deployment fits the bill perfectly.

- Historic Properties: In areas where buildings and landscapes must be preserved, UV Curing ensures that no structural or aesthetic damage is done during the repair process.

Whether it’s a small home or a large commercial complex, UV Curing provides an effective repair solution without the hassle of traditional excavation methods.

Advancing Pipe Repair with UV Curing

At Trenchless Pipe Repair of NH, we’re not just fixing pipes; we’re advancing the way pipe repairs are conducted. Our adoption of UV Curing technology reflects our commitment to innovation and our dedication to providing our customers with the best possible service. By incorporating this cutting-edge technology, we ensure that our repairs are not only efficient but also long-lasting and minimally invasive.

Ready to Experience the Benefits of Modern Pipe Repair?

If you’re facing pipe troubles or simply want to ensure your property’s plumbing is in top condition, don’t hesitate to contact us. Our team at Trenchless Pipe Repair of NH is here to provide you with efficient, environmentally friendly, and cost-effective repair solutions. Experience the benefits of UV Curing and safeguard your property’s infrastructure with the most advanced technology available. We look forward to assisting you with your pipe repair needs and ensuring your plumbing system functions flawlessly for years to come.

Contact

Our Team Today

For more information about us or any of our trenchless pipe repair or replacement services, get in touch with us at Trenchless Pipe Repair of New England today. Call our team or fill out the form to schedule an appointment. Make your stress our stress today and let us help you get back to normal life with your family or running your business and serving your own clients and worry about more important things…like how the New England Patriots or Boston Red Sox are going to do next year.